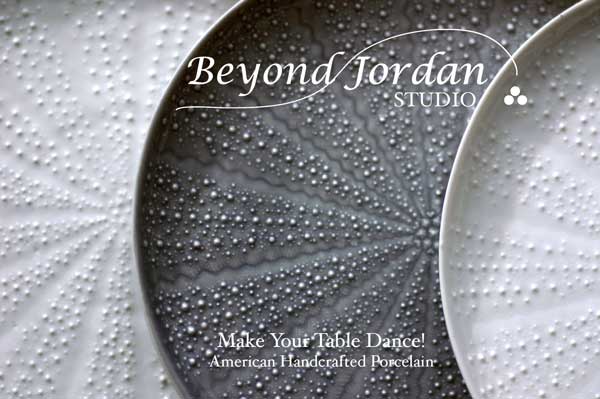

Sea Urchin Plate - New Tools for a New Design

It's been about a month since our last report, and we wanted to get out a quick update on the progress of our new Sea Urchin Plate design.

A New Tool

We use a hand-cranked two ton press on many of our other production processes but found that it created insufficient pressure for this new design (the smaller press on the table).

The Sea Urchin "bumps" were flat, nonexistent, and in some cases very uneven in various sections of the plate with this press. So in the last month, we searched and acquired a five ton press from halfway across the country to do the job! From 4,000 pounds of pressure to 10,000 pounds of pressure makes a world of difference in our ability to transfer our design's details to the clay body of this new plate.

A New Design

And.they.look.beautiful! (see below)

We couldn't be any more pleased with how gorgeous these new plates are coming out!

Except that now each and every mold breaks during the pressing of each and every plate. (One mold should last 30-40 plates before being discarded due to loss of detail definition) Ouch! So much pressure is now being exerted that the actual mold material can not stand up to it!

So . . . we're developing some new formulae so our molds can stand up to producing one Sea Urchin Plate after another, after another. We think this new formulae will be in place in the next month or so. Until then, we hope you enjoy and dream about how beautiful these plates are going to be in your dining room!

The first few plates in "production test" (noted above) came through the kilns and glazing process this past week. We hope you enjoy this behind-the-scenes story and look!

Aren't they beautiful . . .

We can't wait until we're ready to offer the "First Firing" opportunity to our e-community friends! Soon. Very soon.

Jay & Jan